Frequently Asked Questions

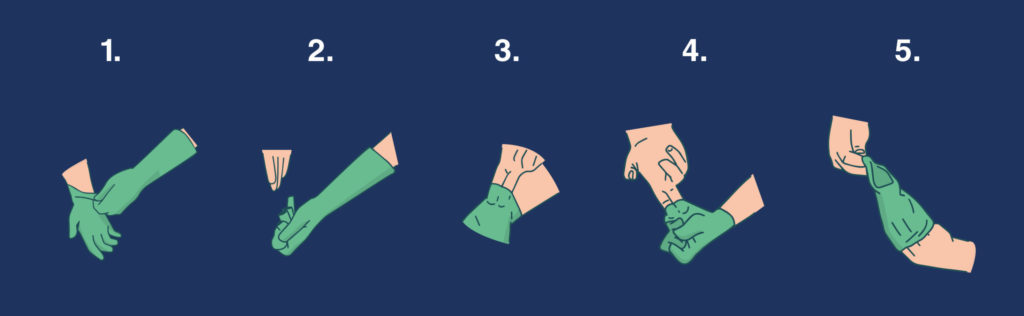

To properly remove the gloves from your hands you need to:

- Pinch and grasp the glove under the rolled edge;

- Turn up the glove until it is completely unthreaded;

- Insert two fingers under the other glove without touching the outer surface;

- Turn the glove up to remove it completely;

- Once the removal is complete, the same sanitization method can also be performed inside the gloves as described in How To Wash And Sanitize Reusable Gloves Wit Soap And Water?

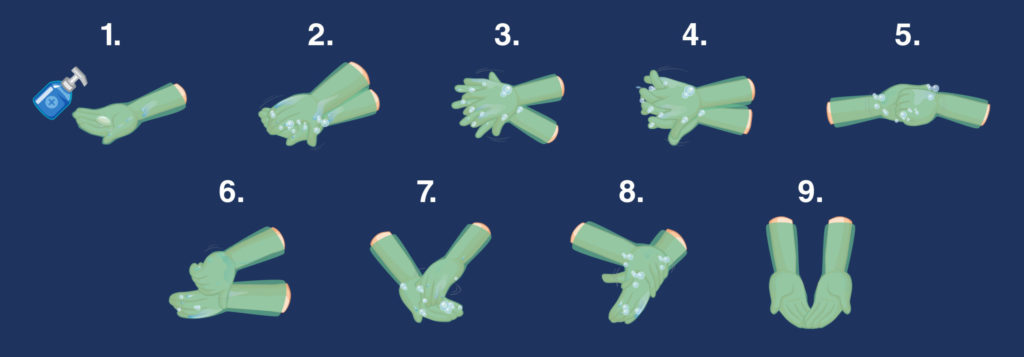

To wash and sanitize reusable gloves with alcoholic gel the following steps must be followed:

- Pour a sufficient amount of solution on the palm of the hand;

- Rub your hands palm to palm;

- Rub the palm over the back and vice versa;

- Rub palm to palm with fingers crossed;

- Rub your fingers with the opposite palm and vice versa;

- Rub the right thumb into the left palm and vice versa;

- Rub by rotating the fingers back and forth in the palm of the hand and vice versa;

- Rub the wrist by rotating the fingers of the hand back and forth and vice versa;

- Once dry, the gloves are clean.

Once the PPE has been sanitized, you can start or resume work using the PPE selected and indicated in the DVR (Risk Assessment Document) of your workstation.

NB: A similar procedure is indicated by the WHO for cleaning hands.

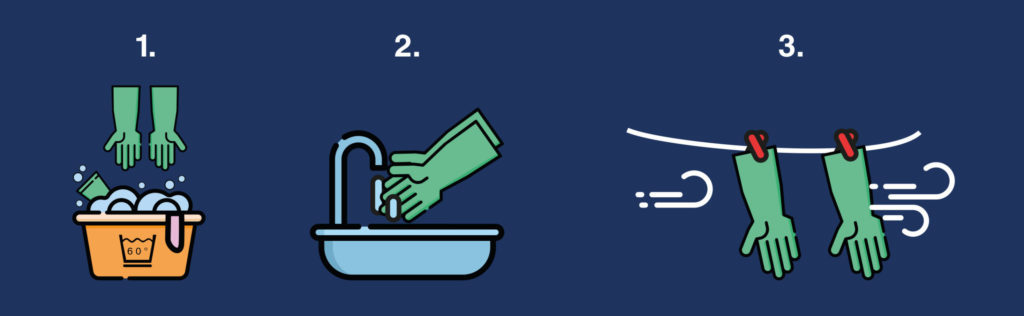

To wash and sanitize reusable gloves with soap and water, follow the following steps:

- Wash with water and neutral soap at a temperature of 60 ° C, completely immersing the glove, in order to remove impurities;

- Rinse the gloves thoroughly under running water;

- Leave the gloves to dry in a ventilated area, in the shade and at room temperature away from heat sources.

Once the above has been carried out, it is possible, after checking for the absence of holes and cracks, to start or resume work using the PPE selected and indicated in the DVR (Risk Assessment Document) of your workstation.

When it does not release chemicals in processed foods, i.e. when it is not harmful to health and does not alter the organoleptic characteristics of foods. Therefore, in order to be declared suitable for food, a product must undertake to carry out tests (global migration in food simulants), which mimic glove behavior in contact with all food categories (aqueous, acidic, alcoholic, Milk, Oils and Fats) in accordance with current regulations (Reg. CE 1935/2004, DM 21.3.73, Reg. EU 10/2011 and subsequent updates and amendments).

In recent years consumers of disposable gloves are gradually shifting from the use of pre-powdered gloves to the use of gloves powder FREE. The reasons for this trend are numerous, linked to the fact that powder often causes allergic reactions, which in some sectors may represent a critical element (mainly in food and medical) and that today are available on the market, at an affordable price, different alternative products to powdered gloves that years ago represented the only solution.

Powder was historically a help to wear the disposable glove, but nowadays there are different types of processing, first of all “chlorination”, which makes the glove satin and therefore make it easier to put on even in the absence of powder.

These are tests under standardized conditions such as duration, temperature and medium (food simulant), corresponding to the worst predictable use conditions of food contact material.

The food simulant is a chemical with characteristics similar to the different food categories (watery, acidic, alcoholic, milk, oil and fat and dry foods). See simulating table

Food simulants A, B and C are designated for foodstuffs having a hydrophilic character and are able to extract hydrophilic substances. The food simulant B is used for foodstuffs with a pH lower than 4.5 and the food simulant C is to be used for alcoholic beverages with a content of alcohol of less than or equal to 20% and for foodstuffs containing A significant amount of organic ingredients that make them more lipophilic.

Food simulants D1 and D2 are designated for foodstuffs having a lipophilic character. D1 simulant food is used for alcoholic beverages with an alcohol content of over 20% for dairy products and for emulsions of the oil type in water. The simulating D2 is used for food containing free fats in the surface.

The food simulant E is suitable for dried foods, but migration trials with this simulator will be mandatory from 2018.

It can not be used in contact with foodstuffs that are exclusively hydrophilic (non-alcoholic beverages or beverages with a low alcohol content of less than 5% *, sugars and sugar-based products (molasses, sugar syrups, honey and the like), crustaceans Fresh molluscs in shell, whole fruit, fresh or chilled, not peeled, fresh vegetables, peeled or in pieces)

It can not be used in contact with foodstuffs with a pH lower than 4.5 (vinegar, cider, juice or simple or concentrated vegetable juices, fruit nectars, lemonade, syrup, bitter, vegetable infusions, coffee, tea , Non-alcoholic drinks, energy and the like, flavored water, liquid coffee extract, preserves, yogurt, feta, mozzarella, mayonnaise, mustard).

It can not be used in contact with foodstuffs whose alcohol content is less than or equal to 20% (alcoholic beverages (wines, spirits, beer), desserts, processed fruit in the form of puree, preserves or pasta or in its own juice Or sugar syrup (jams, compote and similar products), processed vegetables in the form of purees, preserves, pasta or in their own juice, fruits and vegetables preserved in the form of alcohol, preserved fish or meat in aqueous medium, eggs (yolk And liquid and cooked albums), water-based sauces, ice creams).

It can not be used in contact with foodstuffs such as whole milk, partially dehydrated milk and partly or wholly skimmed milk and beverages, fermented milk such as yogurt, dairy products and similar products, cream, melted cheese (soft cheeses, cottage cheese and the like) , Cheese preserved in aqueous medium (feta, mozzarella and the like).

It can not be used in contact with foodstuffs containing fat (bakery, biscuit and pastry products with fresh, surface fat, chocolate and substitutes, confectionery with surface fat, fruits and vegetables preserved in oily medium, In the form of pasta or cream, animal and vegetable fats and oils, natural or processed (cocoa butter, lard, melted butter, margarine, other than fruit, nuts, nuts, cherries, almonds, Fats consisting of emulsions of water in oil), fresh, chilled, processed, salted or smoked fish, including fish eggs, fish and oily fish, crustaceans and molluscs (including oysters, mussels, snails ) Preserved or cooked without shell in oily medium, fresh, chilled, salted, smoked meats, processed meat products (ham, salami, bacon, sausages and others) or under Pasta or cream form, oatmeal marinated meat products, natural crusty or edible crustaceans (gouda, camembert and the like) and light cheeses, oats preserved in oats, fried or roasted foods, products other than Fatty character (preparations for soups, broths or liquid sauces, solid or in powder form; Homogenized composite food preparations, ready-made meals, including yeast and yeasts), fatty sauces (mayonnaise, salad sauces and other oil / water emulsions, for example coconut sauces), champagne, sandwiches, pizza and toast Having fats on the surface, cocoa paste, spices and aromas in an oily medium such as pesto, curry pasta).

Nitrile gloves of the ERWAN range are certified absent from the presence of Tiurami. Tiuramids are vulcanization accelerators in the natural rubber process and can cause dermatitis.

Latex is a milky-looking emulsion and hollow texture, which originates in a lymph from the gum trees.

Once collected the Materia Prima can be converted to dry rubber and then stored and used over time for the production especially of car tires, shoes soles, rugs etc.

Or be kept in the liquid state by adding ammonia and in this case (commonly called Lattice) must enter into the production cycle in a short time, mature ripening.

Latex is used for diving products (eg gloves and condoms).

Latex gloves can cause allergy, but in recent years new techniques and prolonged washings at the end of the production process have reduced the content of latex proteins responsible for allergic reactions. Latex allergy is an immediate allergy (or type I hypersensitivity reaction) involving the production of specific IgE antibodies to certain latex proteins and the release of particular cells by substances (such as Histamine) responsible for clinical manifestations. In recent years, thanks to new production techniques, it is possible to state that natural or synthetic latex and low-protein synthetic latex gloves significantly reduce clinical symptoms and allergic sensitivities.

Allergies due to nitrile gloves are rare and clinical manifestations are mainly due to slight redness on the hands and dermatitis located at the gloves contact area.

Vinyl gloves are made of PVC (Poly Vinyl Chloride) and Phthalates (DINP).

The latter are added to the polymer to improve its softness, elasticity and modelability.

Check out our vinyl gloves in the product catalog.

Vinyl Gloves are produced with new generation DINP phthalates and can come into contact with some foods. Phthalates are very water-soluble but migrate very easily when they come into contact with fatty substances and sometimes also in contact with alcoholic and milk products (50% ethanol tests)

Vinyl gloves are therefore only suitable for contact with certain types of foods, and given the many exceptions, we recommend the use of our Food Handling Line Gloves, especially to the users working in food industry.

Check out our vinyl gloves in the product catalog.

The Nitrile gloves are manufactured with Acrilonitrile and Buthadiene, compounding also named NBR, Nitrile Buthadiene rubber.

The Nitrile come at a liquid state whereas the PVC (Vinyl) come from plastic granes melted during the process.

As far as custom duties is concerned the Nitrile gloves are considered Rubber gloves whereas the PVC is assimilated to plastics with different import duties

Have a look at our Nitrile gloves in our catalogue.

Nitrile gloves may cause, in rare cases, delayed allergies also known as IV Type Hypersensitivity Reactions or Contact Allergies due to chemical residues in the production process. In recent years, new gloves manufacturing techniques and prolonged washing treatments at the end of the production process have greatly reduced the amount of chemical additives present on the gloves and, for this reason, reactions to nitrile gloves are very rare.

Yes, the Latex and Synthetic gloves, disposable and re usable, Nitrile and Vynil comply with the various present norms in force in the Medical (93/42/EEC) and Safety (89/686/EEC) sector.

For further information do not hesitate to contact us. We will be at your disposal with expertise and know-how.

The powder used in the gloves is a corn starch bio absorbable by the skin OGM free.

The chlorination is a special chlorine-based water treatment, which can be done on line – on line – and in this case the glove is chlorinated inside or off-line – and in this case the Glove is chlorinated inside and outside.

The chlorination can be done on the outside of the gloves to confer a sediment effect and improve some resistance to mild detergents.

There is still no specific legislation on the use of Blue-colored gloves in the food industry, but for a Good Production rule, blue-colored gloves are preferred because Blue is the least present in food. Some factories have spectrograms for detecting such color objects on the production lines.

The powder used in the gloves is a corn starch bio absorbable by the skin OGM free.

The powder used in gloves is cornstarch and does not contain gluten. For this reason, disposable gloves with powder can also be used in the processing of celiac meals.

Nitrile gloves have characteristics of mechanical strength (especially drilling) and chemistry superior to Latex gloves, while maintaining a good elasticity, always very much appreciated in disposable gloves, as it gives sensitivity and ergonomics.

Nitrile gloves are therefore preferred for those jobs where greater mechanical and chemical resistance is needed, as well as for those who are allergic to natural latex proteins.

Nitrile disposable gloves are also suitable for contact with various types of food and are increasingly used for handling foodstuffs.

Nitrile gloves are much more resistant than Vinyl gloves, but more expensive.

The biggest differences are in elasticity and mechanical resistance: for this reason vinyl gloves are less sensitive and break more easily, even with a simple finger press.

Even the glove’s porosity is less controllable during production, thus reducing the protection against nitrile gloves when in contact with body fluids and / or chemicals.

Vinyl having no “accelerators” (present in nitrile production compounds) has less chance of causing IV type hypersensitivity reactions or contact allergies.

Latex gloves are made of Natural rubber, natural origin material (from rubber tree), while Vinyl gloves are produced with raw Synthetic materials (mainly PVC – Poly Vinyl Chloride-and-Phthalates DINP plasticizers that makes plastics soft and pliable ). Latex gloves have superior resistance to tear, puncture and are also more waterproof because it is easier to control the level of microholes, therefore safer for risk jobs eg with biological material. Vinyl gloves, being devoid of natural proteins, can also be used by people allergic to latex proteins. They are also less expensive, but can ensure a level of safety if the thickness of the product is adequate. Latex gloves are biodegradable while Vinyl gloves are not, and must be disposed carefully as the PVC if disposed incorrectly may create dioxin.

Products in accordance with Regulation 1935/2004/EC UE Reg. 10/2011 and subsequent amendments related to products intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/CE. It applies to all materials and objects intended to come into contact with food. We conduct tests for specific Global Migration at specific time intervals and temperatures, using simulants substances, which emulate the extractive capacity of all edible food groups, like the chart below. We also check with specific Migrations tests that prohibited and / or specifically restricted chemicals do not to exceed the permitted levels (for example: Phthalates, vinyl chloride, acrylonitrile etc..). The “i” indicates the need to provide the users with additional informations about eventual restrictions, temperatures and times to which the glove has been tested.

Personal Protective Equipment in accordance with the legislation on safety at work (in accordance with Decree 81/2008, Decree 475/92 in implementation of Directive 89/686/EEC and subsequent amendments). Reference standards EN420, EN374 part 1, 2 and 3.

![]()

Products tested by European Community accredited laboratories and certified to protect against microorganisms. The level of performance 2, shown below the pictogram, indicates an AQL for pinholes less than 1.5, considered an effective barrier against microbiological hazards (microorganisms). Even Directive 93/42/EEC which regulates the Medical Devices requires an AQL of less than 1.5 as a barrier for the biological fluids and microorganisms.

![]()

Products tested by European Community accredited laboratories and certified to protect against specific chemicals, indicated by special symbols (eg. K= sodium hydroxide, L= sulfuric acid, G= diethylamine) for specific lapse of time called permeation times. For correct use see the Tech. Files available upon request.

![]()

Products can be used as medical devices in accordance with Directive 93/42/EEC (in accordance with EN 455 part 1,2,3 and 4) – Directive 93/42/EEC on Medical Devices, provides the requirements for the production of gloves to be worn in health care (and therefore for dental use), as well as labelling requirements and assessment of biosafety and validity. The gloves considered Medical Devices provide protection from cross contamination for both the patient and the user as they are considered an effective barrier to fluids and microorganisms.

![]()

AMERICA

AMERICA SCANDINAVIA

SCANDINAVIA SPAIN

SPAIN RUSSIA

RUSSIA AFRICA

AFRICA AUSTRALIA

AUSTRALIA